Optimizing nitrogen removal from wastewater

Optimizing biological nitrogen removal process by Optoseven FSA-CT1000 analyzer. Responsible and cost-effective wastewater treatment in Lahti.

Ali-Juhakkala wastewater treatment plant

Lahti Aqua group is responsible for 140,000 citizens’ water management in Lahti and Hollola. The operating range covers four wastewater treatment plants: in Lahti Ali-Juhakkala, Kariniemi and Nastola, and one in Hämeenkoski, Hollola. The group’s parent company is Lahti Aqua Oy and the operative water management services are managed by Aqua Palvelu Oy.

The wastewater treatment plant in Ali-Juhakkala was built in the beginning of the 1960s. The latest big renovation was done in 2005 when nitrogen removal was also implemented into the process. The daily rate of flow at the treatment plant is approx. 14,000 m³/d.

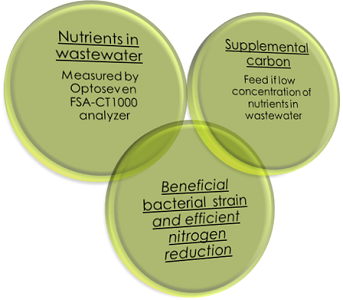

Although the required permit conditions of nitrogen removal are easily met, Lahti Aqua purchased Optoseven FSA-CT1000 UV-COD liquid analyzer to optimise their biological nitrogen removal process.

Optimizing supplemental carbon feed of wastewater

At Ali-Juhakkala, the FSA-CT1000 analyzer measures the pre-sedimented wastewater of the wastewater treatment process. The analyzer measures the organic substance and solid substance.

The amount of organic substance has been added as an input variable to the manually controllable addition of glycerol.

“The measurement results help us estimate, if there’s enough of nutrients for the biological nitrogen removal or do we need to add glycerol. The results complement the gaps in between laboratory analyses and also confirm the analysis results. It’s possible that in the future the pumping of excess sludge can be optimized and reduce the costs of energy and iron sulphate which is used as a chemical coagulant”, says Tapio Kilponen, process-engineer at Aqua Palvelu Oy.

The operating of Lahti Aqua is very responsible. The purpose of optimizing the addition of glycerol isn’t primarily to lower the costs of glycerol but to further decrease the nitrogen emissions that affect the delicate river Porvoonjoki. With the measurement results the nitrogen emissions can be minimized cost-effectively.

Reliable measurement

Usually, the challenges in wastewater analysis are caused by contamination of the measuring devices, that make the results unreliable. The self-diagnostics of FSA-CT1000 analyzer tells the effects of automatic cleaning, so the painstaking manual cleaning is not needed, and the measurement results are reliable.

”After the installation, the analyzer´s cleanliness signal indicated contamination problems. After we found the proper cleaning parameters, the analyzer has been working completely maintenance-free”, Kilponen continues.

The sample is automatically analysed in the measuring chamber, which is located inside the analyzer. This way, the analysis happens in reliably comparable and known circumstances.