Circular economy

Circular economy is practised at many industry sectors to save global recourses. Slightly contaminated water is often conveyed to the less sensitive processes to decrease the raw water intake and waste water generation. To improve your ecological footprint and profit savings the re-circulating rate can be optimized without the fear of damaging the quality of your final product by using Optoseven FSA-CT1000 liquid analyzer.

Washing process monitoring

Clean process lines are mandatory, e.g. in the food industry. Cleaning the process lines not only consumes a lot of water, but the time is also out of production. By Optoseven FSA-CT1000 liquid analyzer the waste water from the cleaning process can be continuously monitored and the washing operation can be optimised. For example, milk residues can be monitored down to ppm levels in the grey water. Optimising the washing operation reduces the down time of the process, clean water use and the waste water generation.

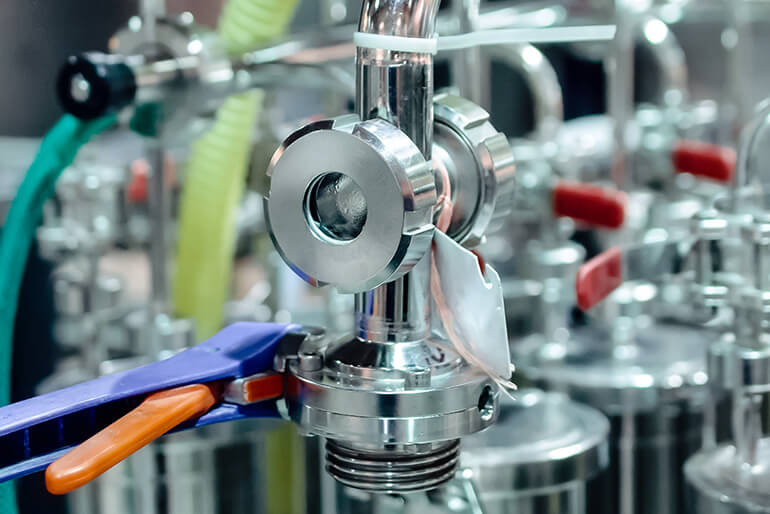

Chemical industry

The chemical industry has unique processes and they often have special needs for analytical systems. In co-operation with us, also customer based novel analyzer solutions can be rapidly developed to measure different parameters from the sample liquid. Analyzers may be used for a process control, monitoring, or to continuously analyse the quality of your final product.

Greenhouse industry

At the greenhouses, Optoseven FSA-CT1000 liquid analyzer can measure nitrate, organic matter content and turbidity of the growth solution. By connecting external lighting sensors to the analyzer, it can be used to optimise the fertilizer use at growth solution and power consumption of the lighting. Thus promoting the quality of the final product and causing direct cost savings.

Application note(s)